Damage Examples

Below are examples of electric discharge damage

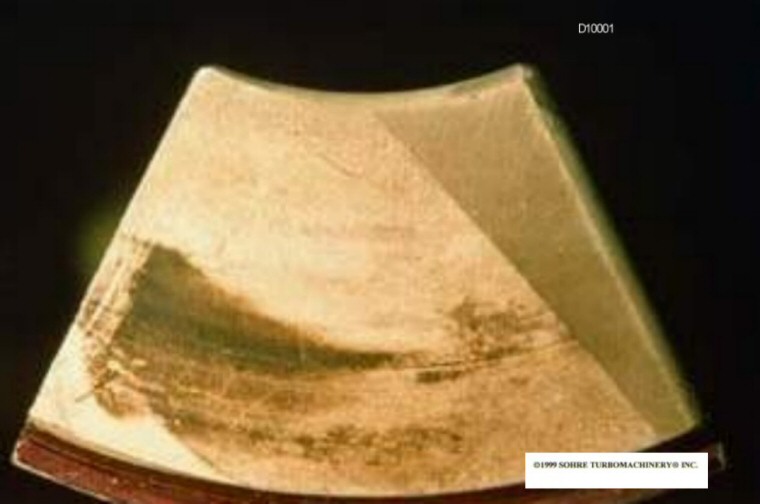

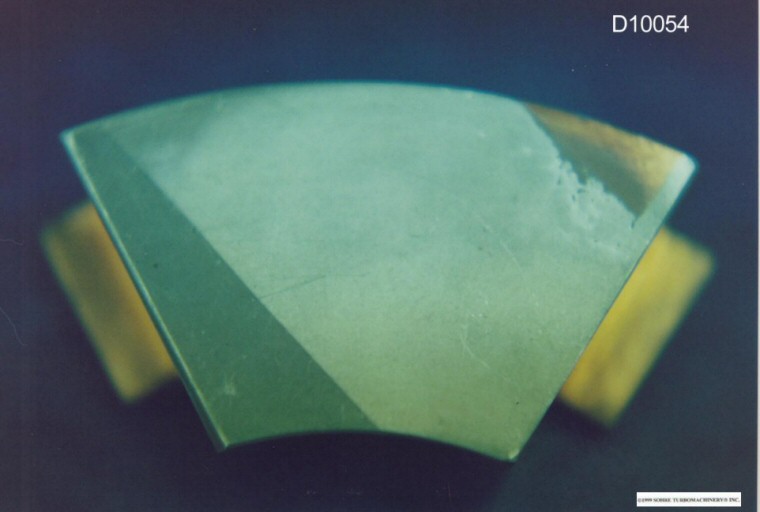

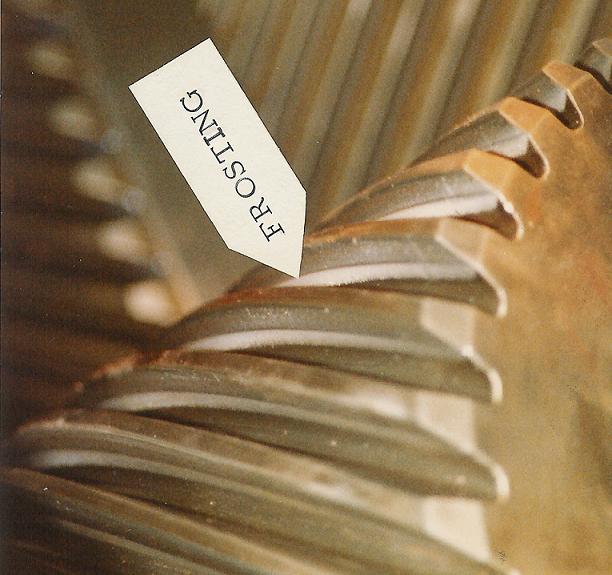

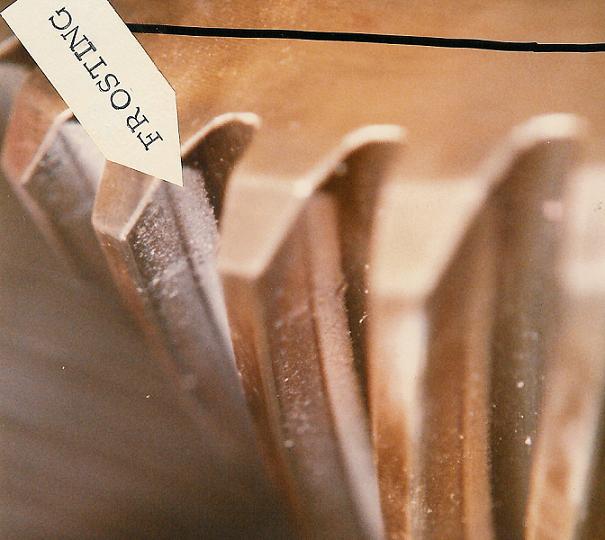

D10001 – Thrust shoe severely damaged by currents (frosted area). The wedge-shaped area at leading edge (right) is the only remaining original surface. At the white triangle at trailing edge, outside diameter, the babbitt is completely gone and spark erosion has progressed into the steel backing. Metal lost at this point is 0.085″. The dark area is oil cake. Bearing was close to failure.

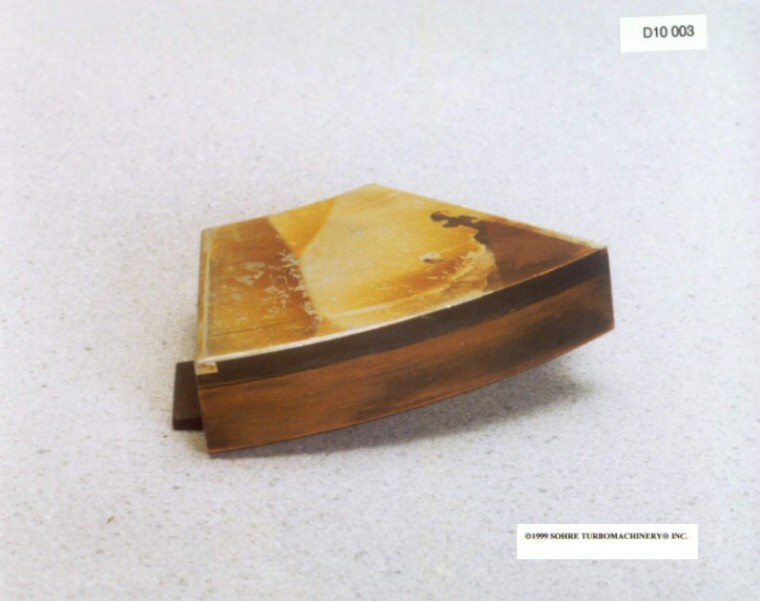

D10002 – Surface of thrust bearing shoe which shows damage due to spark erosion. Note how babbitt surface has been progressively eroded going from right to left. Original babbitt surface is at lower right.

D10003 – Surface of thrust bearing shoe which shows damage due to spark erosion (same item as d 10 002). Note how babbitt surface has been progressively spark eroded going from left to right. Babbitt has been completely removed at lower right corner.

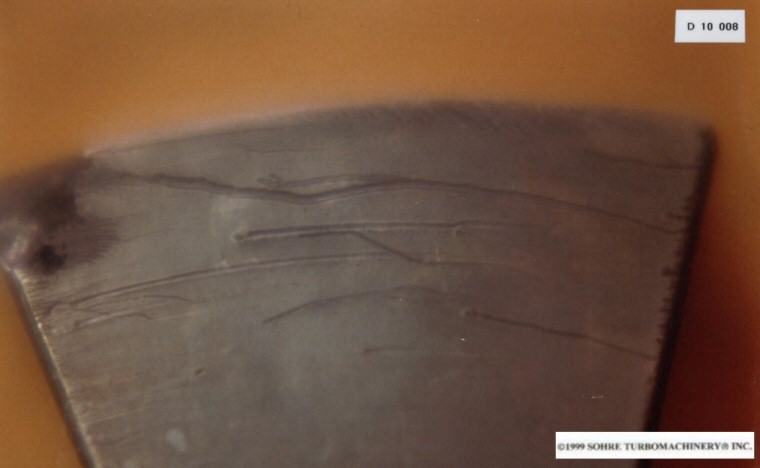

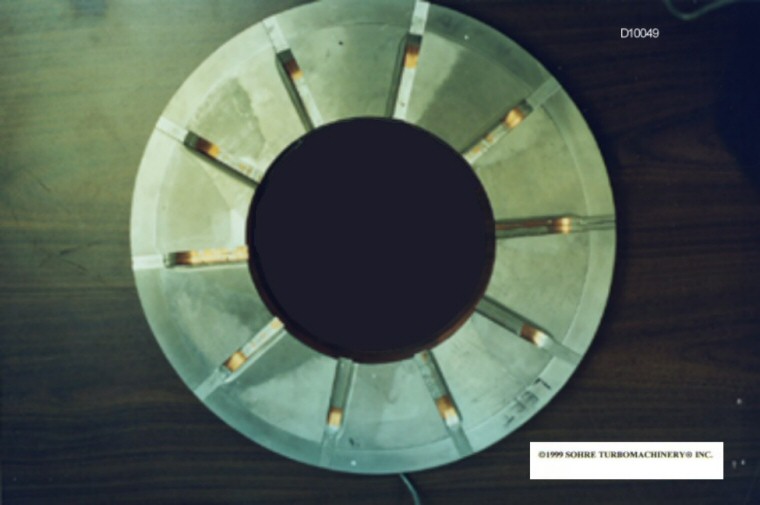

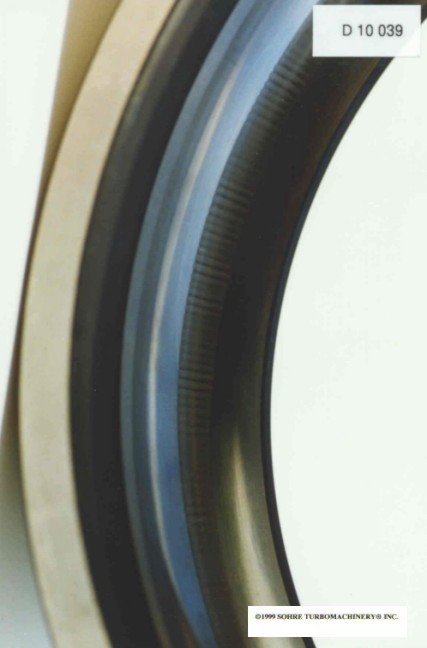

D10009 – Fixed pad thrust bearing showing moderate amount of frosting due to spark erosion. Unit was equipped with OEM carbon brushes.

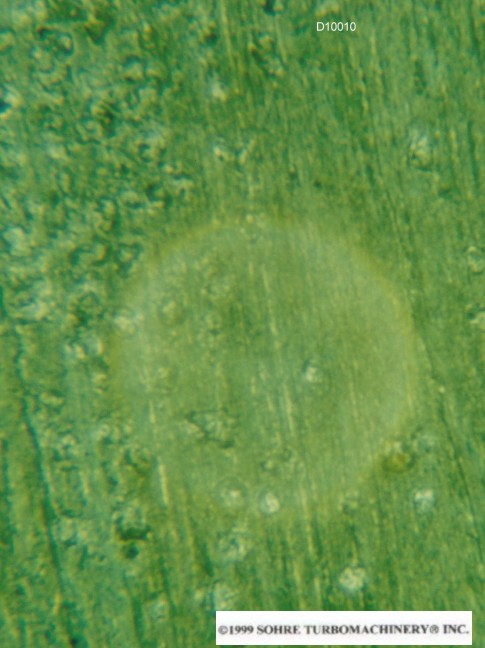

D10010 – Boundary between “Frosted” area and original surface as seen through 30x microscope. Same bearing surface as shown in d 10009.

D10049 – Fixed pad (tapered land) thrust bearing surface damaged by spark erosion. Full view of bearing. Same bearing as shown in d 10009.

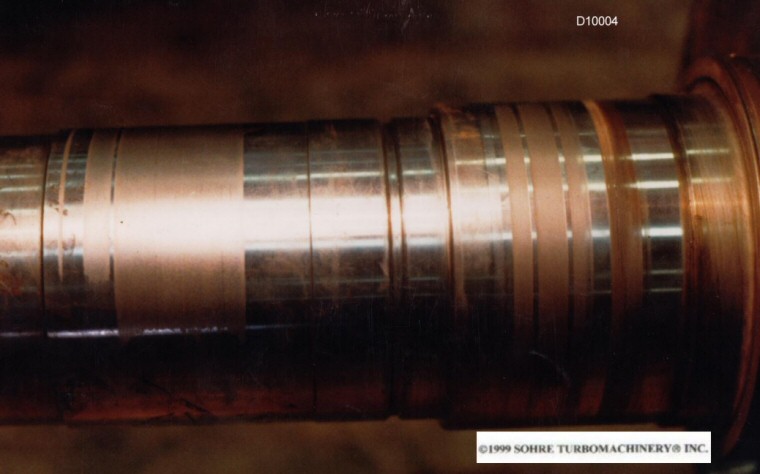

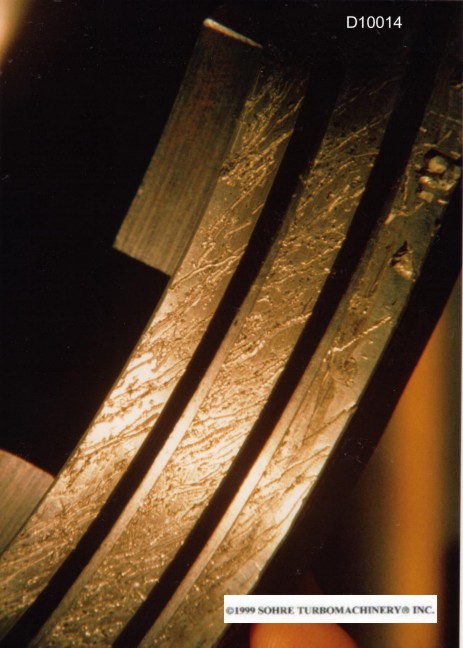

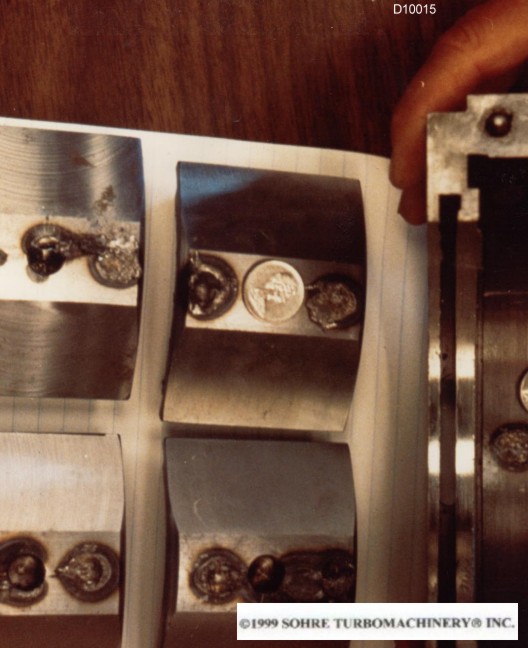

Bearing shoes (steel) welded to bearing cage during final episode of self-excitation and consequent thrust bearing failure. Ammonia plant, air compressor turbine, 10,000 hp, 8,000 rpm.